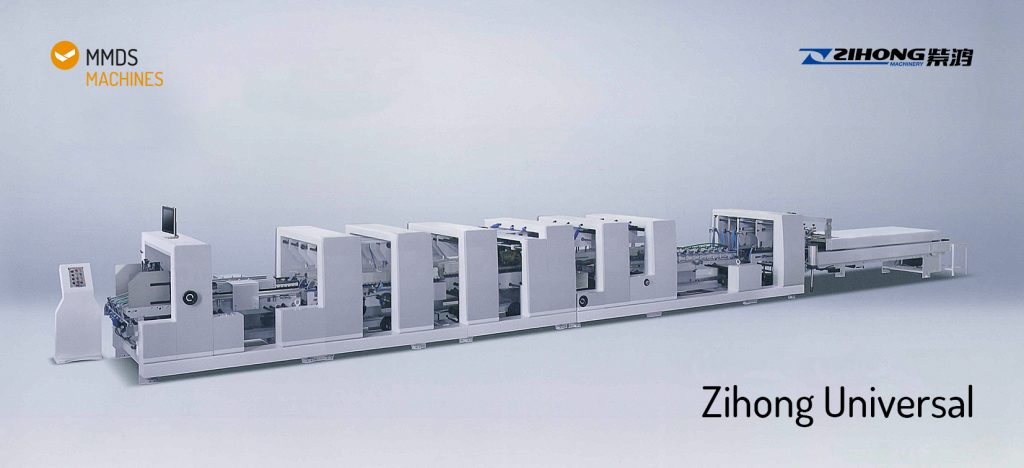

- Technologically advanced folder-gluer for cardboards and corrugated boards

- For the production of straightline boxes

- For the production of double sides boxes

- For the production of crash-lock bottom boxes

- For the production of 4/6 corner boxes

- Pre-creasing section of 1 and 3 crease (pre-folding)

- For the production of straightline boxes

- For the production of double sides boxes

- For the production of crash-lock bottom boxes

- Pre-creasing section of 1 and 3 crease (pre-folding)

- For the production of straightline boxes

- For the production of double sides boxes

- For the production of crash-lock bottom boxes

- For the production of straightline boxes

PACKAGING LINE

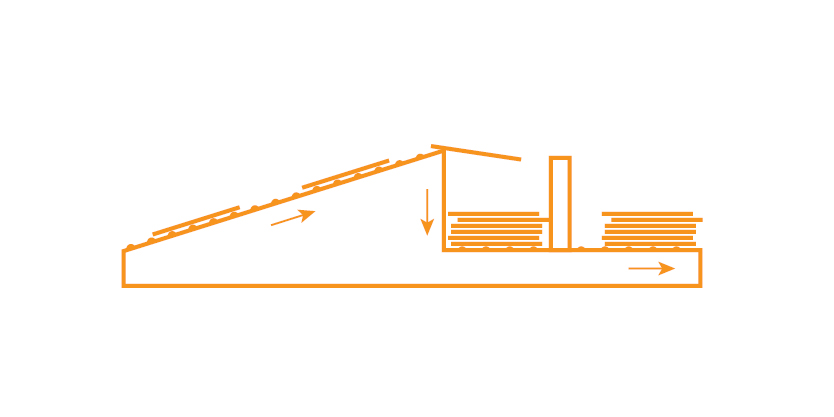

Stacking module

- Conveyors driven by an inverter-controlled motor

- Automatic counting and stacking without box damage

- Quick machine setup

Levelling module

- Box dimensions: L 300-1000 mm, W 300-1200 mm, H 1200-350 mm

- Max package weight: 25 kg

- Speed: 20 m/min

Automatic clamping device (PP strap)

- Width of PP strap: 5 mm, 9 mm, 12 mm

- PP strap thickness: 0.35-0.65 mm

- Speed: 30 m/min

CHARACTERISTICS

- Modular construction

- Designed to work with solid cardboard (210-900 g/m²)

- Designed to work with 3- and 5-layer corrugated cardboard

- Speed: up to 350 m/min

- Automatic feeder with inverter-controlled speed control

- Levelling section – levelling of product on both sides of the machine

- Pre-folding section of 1 and 3 crease (Optimal and Universal)

- Back-folding section (Optimal)

- 2- or 3-point HHS top gluing system with customizable 2 lower gluing wheels on both sides of the machine

- Folding section

- Trombone section – stacking section with independent drive

- Pressing section

Additional options

- Additional creasing in the pre-folding section

- Plasma with two guns in the gluing section

- Hot-gluing system with two guns

- Option of gluing levelling in transfer section

- 90° reversing module